An article in the June 2020 edition of Safety Fast! Roger Cooper wrote a detailed way to keep the rust at bay. Read the online version here

General Tips for MGB Owners

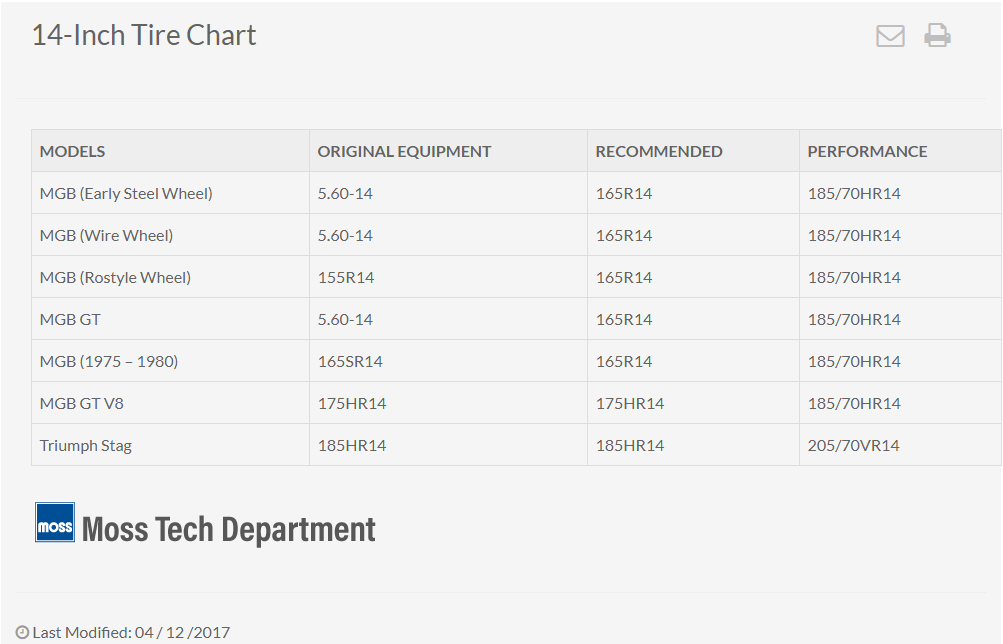

Video about the availability of classic tyres for the MGB through Longstone Classic Tyres.

10An article in the August 2014 edition of Safety Fast! about the MGB boot created a lot of interest and discussion. The article plus some of the comments and the original photo (the one in the Safety Fast! article was slightly cropped) can be downloaded HERE.

There are many videos on YouTube produced by John Twist in the USA.

If you want wiring looms the best is Auto wire. ChicagolandMGclub has a good selection of technical articles and MGStuff is also very useful.

A comprehensive list of what you will need in case of a breakdown on the road.

Download PDF here (37 kb)

“Intro” to the MGB including “Development”, “Buying”, “Maintenance”,

“Production Development Changes” and “Touring”.

Download the Buyers Guide (1.5 mb)

When starting your engine from cold on cars with manual transmission you should have your foot ‘OFF’ the clutch pedal and the transmission in neutral. Why? When you depress the clutch pedal you place a very direct force on the crankshaft thrust washers and with no oil pressure in the cold engine more wear will take place than needed of the thrust washers.

The wear will not be so great on an engine that has recently been operating and has all the parts well coated with oil. However its always a good idea to get into the habit of starting the engine with the gear lever in neutral and your left foot off the clutch.

As you rarely use the jacking points on your MGB, you are likely to have difficulty in an emergency in getting the jack into the jacking point sleeve due to it being filled with mud and rust. To overcome this thoroughly clean the sleeve, give the surface a good coating of grease.

Buy from a DIY or Sports shop four walking stick rubber ferrules to seal either end of the jacking point sleeves. Hopefully next time you need to use the jack it will be easily located.

If a little grease is good, more grease is better- right? Well it ain’t necessarily so!

The owner of a MGB decided to lubricate his new speedo cable, something which isn’t really necessary but after a period of time he noticed that the speedo needle would slowly move to the proper speed but would not return to zero when the car stopped.

Finally the speedo was removed from the car where on examination it could be seen that the rotation of the cable had forced the grease through the drive gears and into the magnetic cup. This completely fouled the unit.

It took quite a bit of cleaning with a spirit degreaser to remove all the grease plus removing the inner drive cable to try to remove the excessive grease, after which the speedo was soon returned to normal working.

A new speedo cable should not require any additional grease however if you do decide to add grease a little bit will not hurt – but please not to much! Also remember that a cable driven speedo rarely fails and if the needle is wavering to any degree it is almost always that you will find the inner cable dry, the cable possibly kinked, the outer casing has been crushed somewhere or it is making too tight a curve.