It’s Not About Chasing Horses

Whilst I like to think that my B GT is reasonably well fettled, I have had a niggling feeling that the fuelling has not been quite right. Travelling back from Kimber House to Somerset on what may have been the hottest day of last year (yes, we did have a few hot days last summer) it showed signs of running rich. Leaning off the mixture to my HS4 carburettors by two flats each saw a 200rpm increase in idle, but then consequently it seemed a little dull in the higher rev range. After a little more experimenting with mixture, and ensuring the carburettors were balanced, I settled for a compromise, and a compromise is never the optimum solution.

Deciding that it would be worthwhile getting an expert opinion, I contacted a local specialist tuning garage in Warminster, Lloyd Specialist Developments, and booked the B GT for a half day on the Dyno. Family owned, Nathan and Dan Lloyd specialise in Rover V8’s but are quite accustomed and experienced with working on B series, amongst most other classic and modern, engines. They operate a hub dyno system as opposed to a rolling road, giving highly accurate results given the variances that can occur by the contact of the tyre to the roller.

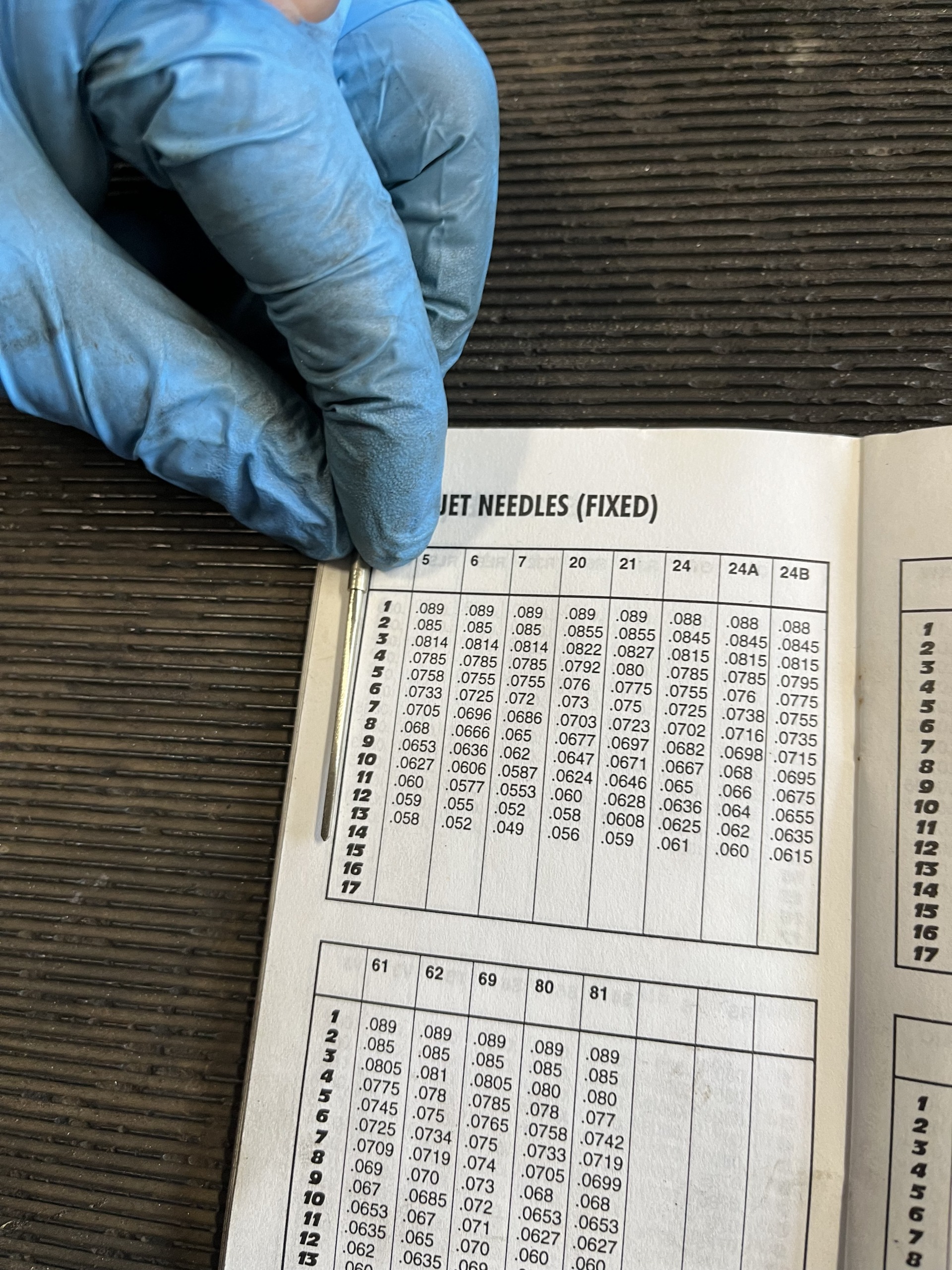

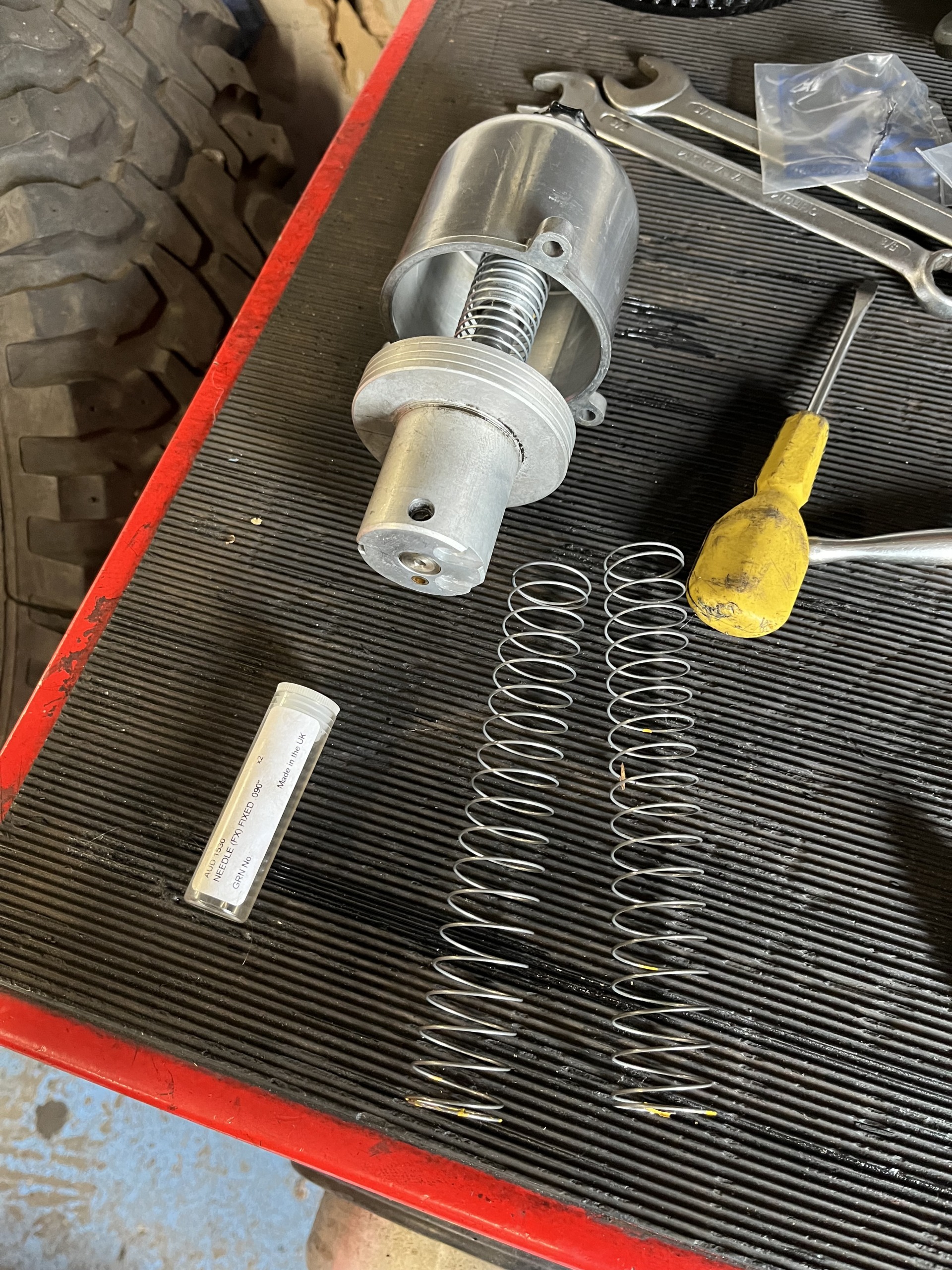

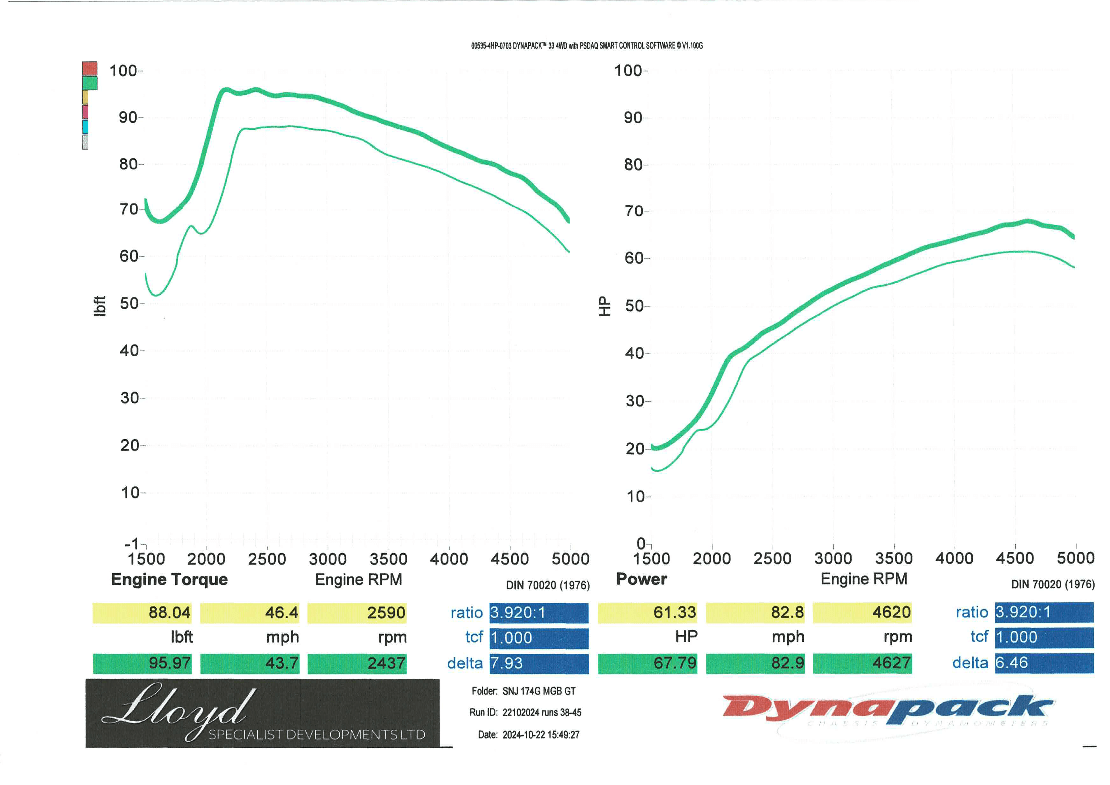

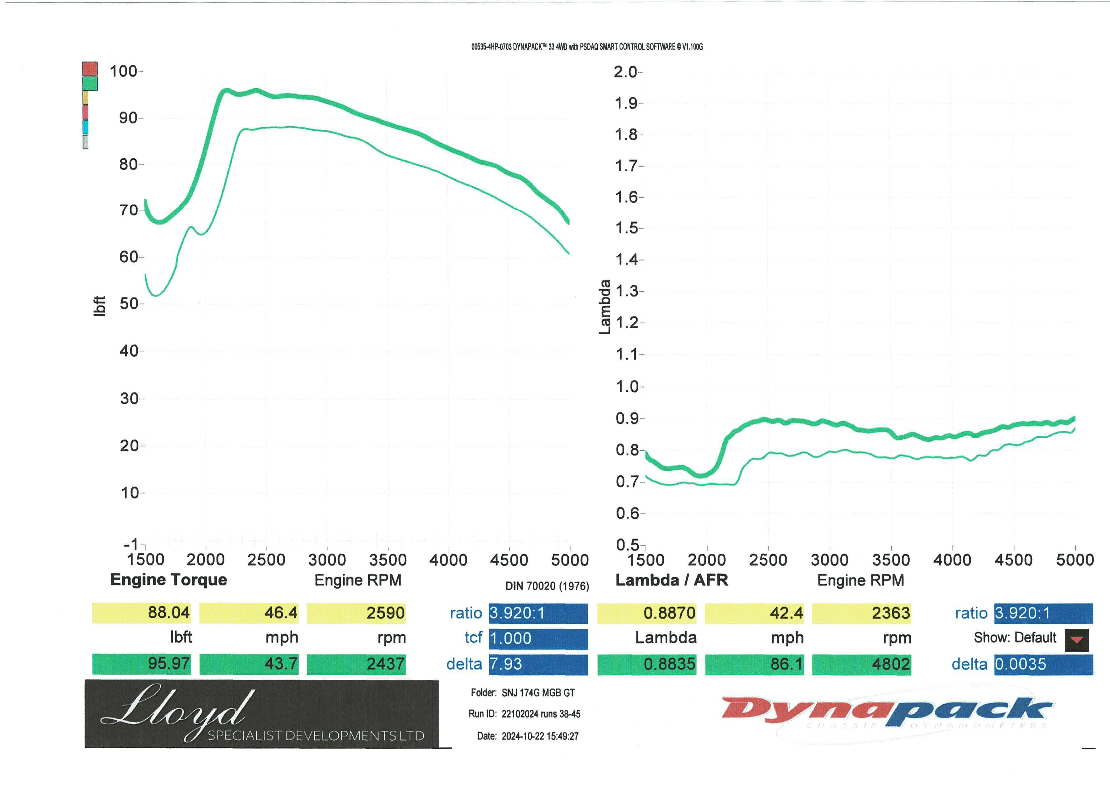

On the morning of tuning, Nathan assisted by his young but already knowledgeable assistant Cory, quickly set about the baseline dyno runs which identified a generally rich mixture from idle through to about 2,250rpm where the air flow ratio rose sharply to a more respectable level just below 0.8 Lambda before leaning out from 4,200rpm. Acting as the datum the idle mixture was corrected to 0.8 Lamda, but still with the mixture being too rich in the 1,500 to 2,250rpm range and too weak above 4,200rpm, but that’s the starting point. Whilst the carburettors were found to be balanced at idle, it was found that the pistons were not rising uniformly and a simple adjustment of the front throttle lever on its shaft corrected for this. There followed the iterative process of removing the dash pots and floats and dyno testing each adjustment made in respect of position of the needles and filing of the needle profile. After many adjustments and dyno runs Nathan was reasonably happy that he had a better fuelling profile, in the high 0.8 Lambda range without the weakening in the higher rev range. However, the richness remained in the low rpm and there was a feeling that we were chasing our tails and time to call a stop to it.

With fuelling achieving an acceptable profile attention turned to timing. As expected, the advance was found to be 10degrees, but I had some old notes on file showing that tuning 10 years previous had found 13degrees to be optimum. Sure enough, this adjustment produced a positive result and we were closing in on a good set up. The Ignition123 profile was checked and confirmed to be the MGB stage-2 curve, but Nathan felt that an alternative curve with 26degree advance at 5,000rpm was worth a try. Sure enough, this resulted in the final and significant uplift in performance for the day.

45 power runs, 7 hours and 4 tea rounds later and the engine performance had improved significantly from the baseline results. Other than a significantly better fuelling profile across the rev range, all important engine torque had risen by 9%, from 88.04 to 95.97 lb.ft. Power at the hub had increased from 61.33 to 67.79 bhp, a respectable 10.5% uplift.

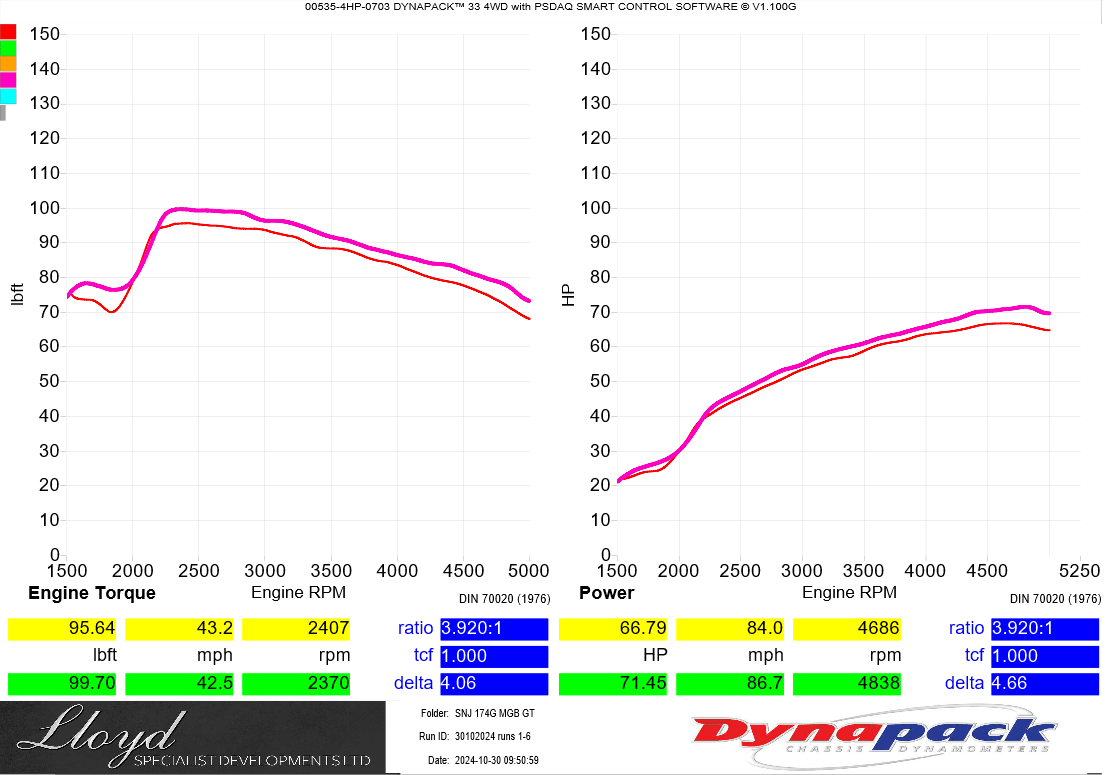

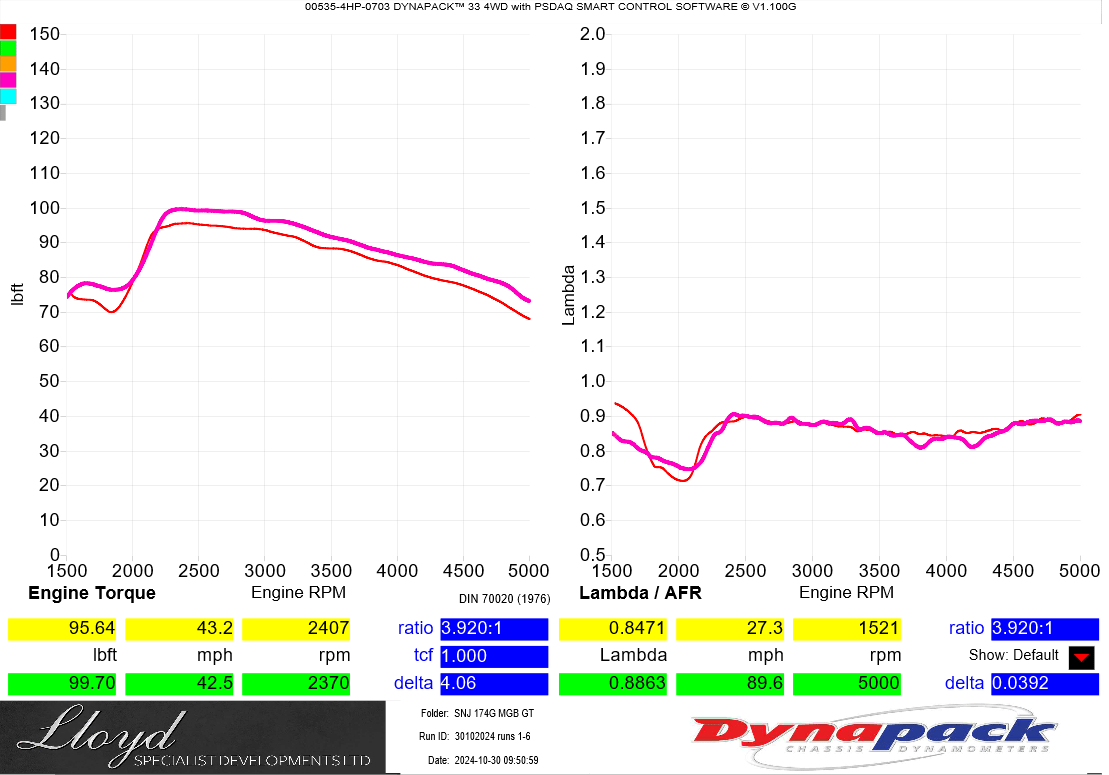

After a few test drives and subsequent phone conversations with Nathan it was agreed to try going back to ‘stock’ with standard needles, FX replacing the Type 6 ‘Rich’ and 4.5oz red springs replacing the 8oz yellow ones and so a repeat visit was arranged. After a quick baseline dyno run to establish a new starting point, the change of needles and springs were made and tested. Going ‘stock’ made a significant improvement with a clearly more respectable fuelling profile across the rev range. Power rose to above 72bhp and 100 lb.ft. A few minor tweaks were made to the needle profile and a slight change to the timing resulting in final figures of 71.45 bhp and 99.70 lb.ft, an increase of 16% and 13% respectively.

Applying the rule of thumb 45bhp loss from crank to wheels would give a likely engine output of about 117bhp, just above to the 112bhp measured on a rolling road after installing the Oselli engine ten years previously.

A meeting at Kimber House required a Sunday morning drive up from Somerset and the chance to see how the newly tuned engine performed on a range of road types, from B to motorway. Most notable is a sharper engine response in and around town, compensating for the stage-2 tuned engine that was previously a little lumpy when driven in traffic. Out on the open road and the power curve is reassuringly even all through the rev range. I was finding myself selecting a higher gear that little bit sooner and also lifting-coasting when cruising on the motorway significantly more, all of which must be good for fuel economy and after a 200 mile trip on mixed road types the newly tuned set up achieved 32 mpg. But none of own and drive our MGs for fuel economy.

My B GT goes in to winter slumber once the road salting starts and it won’t be until early March that it re-emerges for anything other than a weekly run up the local un-salted road to keep all things turning and lubricated. However, I’m confident that come the MGB Register Spring Run my B GT will be flying along with renewed vigour along the lanes of the Chilterns to Stowe House and that I’ll have a spring and summer of joyful motoring ahead. It has to be said that this level of refinement is not wholly necessary, but it is the icing on the cake on an already very well sorted B GT.

Neil Brant

The Classic MGB Youtube channel filmed the full tuning process and can be viewed on their channel. https://www.youtube.com/watch?v=O744ZiyUb0E