Boot floor trouble

Thomas Aczel shares his story of the issues he found after lifting his boot carpet.

I’d long regretted carpeting the boot in my MGB, (in 1985), but with its bare painted floor, articles being carried in the boot were forever scratching and marking the painted surfaces. It just never looked tidy, always deteriorated and “unfinished”.

So, 35 years later, I finally got around to taking the carpet out again.

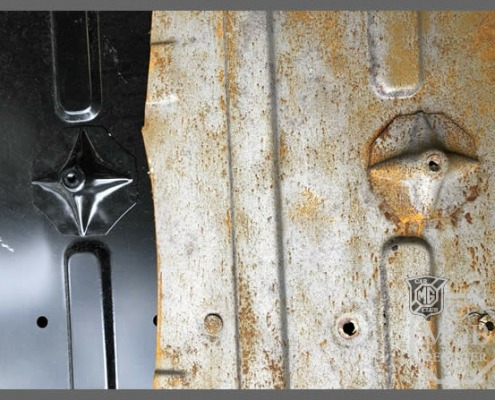

Initially, things didn’t look too bad! Just a lot of hard rubbing, leaning over into awkward angles. BUT, around the fuel filler, clearly things weren’t so happy. Much rust, which looked like surface rust predominantly. But also emerging were former patch repairs (x2) to the boot floor, and, as you can see in the photo with the screw driver pointing, some small perforations appeared in areas well away from where corrosive and rust promoting fluids had collected in the off-side rear quarter recesses.

One significant disadvantage of having to go to work was my not being home when the soda blaster came. He had assured me that he could protect the surrounding paint and only blast in the boot. Nonetheless I carefully masked off around and inside the boot carefully, including boot lid hinges, prop, wiring harness and filler neck. I also masked around the perimeter of the vertical panel separating the cabin from the boot to stop the dust getting in to the cabin. To mask inside the cabin, I removed the parcel shelf carpet. Unfortunately it would seem the this was interpreted by the soda blaster as me asking for the parcel shelf to be blasted, which was entirely unnecessary. The result was a cabin with dust everywhere! In some places there actual piles of sodium bicarbonate a centimetre and more high, and in many places forced into narrow inaccessible crevices.

Small pinholes, and more than just pinholes (!!) and not unfortunately not localized to just one area. Things are looking more serious!

The last photo is of some of the foam I extracted, placed on each side between the corner boot floor panels behind each wheel arch on the sides and the inner surface of the mudguard, still there from when the car was first assembled in Enfield, Sydney, at Pressed Metal Corporation, in September 1965. It was all still in there, intact and complete, and, remarkably, utterly dry.

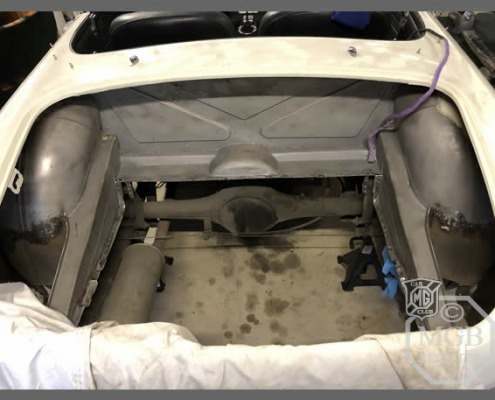

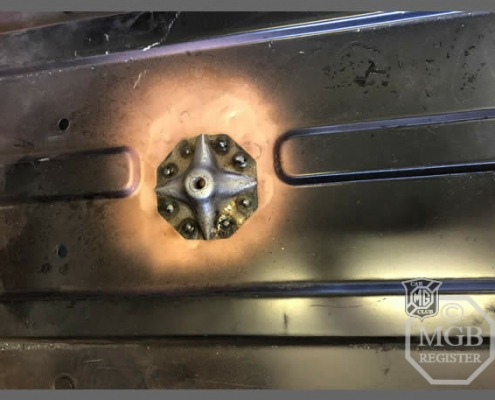

As the photos demonstrate, the two boot floor corner sections have been put in now. Predominantly as a result of the previous insertion of a repair section in the trailing edge of my boot (circa 1977) with a slightly inaccurate radius, the near side panel took quite a deal of fettling by Robert to allow it to fit nicely.

The main section of the boot floor is next. The reproduction panel had serious discrepancies from the original. The panel now sourced from British Motor Heritage is better, but is roughly produced, poorly finished and still shows differences from the original, which will unfortunately need further time consuming attention by the artisan Robert.

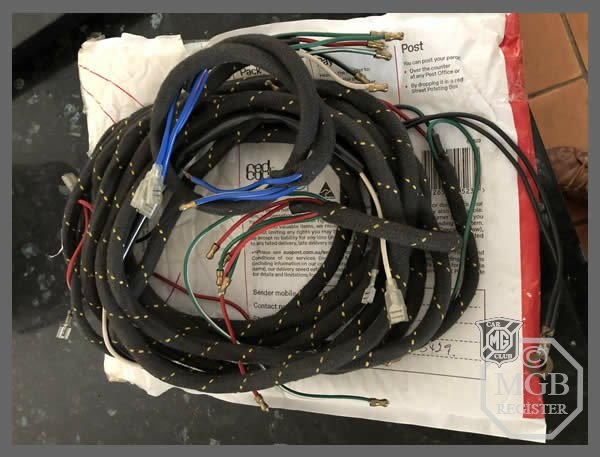

Another discovery from taking out the boot carpet was that the wiring harness had been cut into, spliced and wrapped in PVC tape. I have no idea when this happened, by who, nor even why. The car had been rewired in 2006, using a brand new cloth-wrapped wiring harness. So it was fortunate that a new unused early MGB rear harness came up for sale recently at a reasonable price.

And poor Robert got into all this by having very kindly offered to repaint the interior of my boot in readiness for my upcoming Easter road trip in my MGB to Wodonga! He may understandably be reluctant to ever again help me with a seemingly small task on one of my MGs again. The Wodonga trip has since been cancelled. Hmm…Robert, I’d love my MGA to be Katoomba Grey again! :-D