Andrew Sharpe’s

Progression into the world of MG’s

A while back I had read the article by Geoff Mansfield on his long way round to owning his first road worthy MG, and it inspired me to jot down my path to my fixation on the MG marque (July 2021 Volume 66 No. 7). I’ve managed to finally finish it and thought I would share with the MG Car Club!

I’m a Kentish lad. Born in 1956 at Farnborough Hospital in Locksbottom, in the London borough of Bromley. My Dad was a Radar Engineer working for DECCA radar. Harold Jewett (his boss at DECCA) was heading to America and was asked to which other young engineers they should be offering a job in the US. My dad was on that list and so he, my two brothers, “me Mum” and I were off to the US as part of the last stages of the “Brain Drain” from Europe. To get Mum’s buy-in, Dad brought a Sears & Roebuck catalog home and after seeing automatic washers to clean “nappies”, mum was sold! We were off to Massachusetts.

My dad was young and in his prime, with other Brits in the same situation. We all clung to each other for Holidays and weekend adventures. After buying our first home, dad and our Brit neighbor (Norman Hollis) each bought brand new 1962 MGB’s. Norman went for powder blue and dad got white with black seats with red piping.

As our house was burned down in the 1990 “Painted Cave Fire” of Santa Barbara, photos are hard to come by. These photos of our last home in Massachusetts show my dad’s MGB in the driveway and Norman pulling into the driveway. The best thing about these photos is that it tells me that the amber front and rear turn signal lenses are correct for US MGB’s.

My sister was soon born and we often had six of us in Dad’s B. Three boys in the back and my sister on Mum’s lap.

I often got to sit in the middle front and was assigned to shift the gears when Dad gave the signal and I saw his foot depress the clutch pedal.

Dad drove all year round, including in the snow. One time he walked in the house and had the “3 boys” walk over the hill with him to where his MG had slid off the road and was stuck in the snow. We all pushed and struggled and finally Dad told me (the youngest at eleven) to drive while he and my two brothers pushed from behind. I was too scared to try. I always wished I’d given it a go!!!

Dad was then given a promotion and transfer to Santa Barbara, California. He sold the MGB and in late 1969 off we went to sunny California without a convertible!

Trips back to the UK happened every other year and they always revolved around driving excursions with my Granddad or Uncle leading and often there were trips to see an Autocross in the farm lands or off to Brands Hatch to watch races or even to the Beaulieu Motor Museum. My uncle (Neil Purton) was also an MG enthusiast posing here with a car at Beaulieu, which he said was the same as his first car – a Midget.

Dad bought our mum a 1971 Austin America. It was a semi-automatic version and each of us used that car to get our drivers’ licenses. My oldest brother, Graham Sharpe, bought a Renault Dauphine for his first car and my next oldest brother, Martin Sharpe, bought a 1960 MGA. I bought that from him for $300 in 1972.

It was soon not running properly and I was tasked to take the engine apart and make repairs. Dad was meticulous and at a distance…oversaw my progress and was available for consultation.

The first requirement was that as every nut and bolt was removed they were put in envelopes and marked for where they belonged. All parts were labeled as to which cylinder or location they belonged so as to go back and fit best in the location to which they had become accustomed. At the end of reassembly there were to be no left over nuts, bolts, washers or clamps or anything. Dad reinforced the rafters in the garage and had purchased a “come along” winch hoist for lifting engines and I soon had the engine and transmission dangling from the garage rafters. Disassembly showed blow-through holes in the outer circumference of the pistons as the premature detonation had broken through the ring grooves. A full rebuild was in order along with new wood floorboards (under coated with black goop of course). We made our own valve spring compressor by modifying a C-clamp. Cleaning, inspection, measurements and much more resulted in a parts order list for Moss Motors on Dawson Ave in Goleta, CA. – luckily for me, only 4 miles from home. The nuances of lapping in valve seats and checking for uniform seal widths, pre-lubrication of plane bearings, ring end gap checking, etc. were all discussed and the merits of “doing it right” explained, and before too long we were back on the road.

Soon after, I learned about “double clutching” as the syncro-rings in second gear had gone. Dad taught me how to listen for the whining sound that they make if you simply pull the gearshift into 3rd coming down from 4th. He taught the proper way to “blurp” the throttle to “match the revs” and not wear the brass syncro-rings, which were intentionally made of a softer material for their purpose.

So, out came the new floorboards and then the engine along with gearbox once again! Rebuilding the gearbox is how I learned the value of exploded views of assemblies. The factory manual was a must, but the exploded views (often using the Moss catalog) always insured the various parts were installed in the correct location AND orientation. Upon seeing the worn syncro-rings, it was obvious that it would not take much abuse to wear them out again. To this day, I still tend to double clutch 3rd to 2nd for good measure and into 1st when needed. A must for the straight cut 1st gear (which can be a bit touchy to get right).

The gearbox rebuild process also taught me how to think of various “tricks” to manage assembly of springs and ball bearings and getting the lay-gear with end thrust washers to stay in place as the lay-shaft is installed.

That was my first car and the lessons I learned from Dad have been invaluable ever since. Carburetor rebuilds, mixture and timing adjustment, differential rebuild, generator armature undercutting, brushes, rectifier/regulator adjustment, water pump rebuilds, speedometer & tachometer rebuilds, preparation and repainting the car, and on and on!

Since then I have owned a 1957 MGA, then a 1960 Austin Healey 3000, a 1965 MGB, two Triumph TR6’s and most recently a 1963 MGB. Each of these cars required various degrees of repair: engines, gearboxes, differentials, brakes, clutch, carburetors and diagnostics to determine what that “odd noise” was…

My oldest brother owns a 1967 MGB and a 1959 Twin Cam (which currently lives in the UK) and my next oldest brother (from whom I bought my 1960 MGA) recently bought a 1958 MGA for his retirement fun and is currently in the process of restoration. My sister, Beverley Sharpe, had her time with British cars, having inherited our Mum’s Austin America. Dad taught her to do all her own service work on it. They bought a second Austin America and used it, as a donor to do a major overhaul on her car, converting the semi-automatic to a proper manual transmission. Beverley was Dad’s support crew for the entire process and became proficient at regular maintenance and readjusting distributor contact points, as her many miles required fairly frequent gapping. So, suffice it to say that the Sharpe family obsession with MG’s is alive and well.

I was teased about Lucas and British car reliability. But I have to say, that I have never been let down by any of those cars. Knowing how to pay attention to your car and listen for changes has always had me finding what could have gone wrong on the road before it was an issue. One time, driving the 1960 MGA home from Mammoth Mountain ski area, we “ran out of gas” with a full tank. Listening and testing showed me that the points on the original fuel pump under the battery cover needed repair. However, for every time I would switch on the key, I would get a click of fuel pump function. So, being without tools, I simply turned the key switch on and off 5 times (quickly) as the car began to stall, it would come back to life, and then a few miles later I’d repeat the process. This was done for several hundred miles in order to get home! That was the closest I have ever come to having to leave my MG by the side of the road. It only cost me a sore finger due to a blister from all that switching of the key!

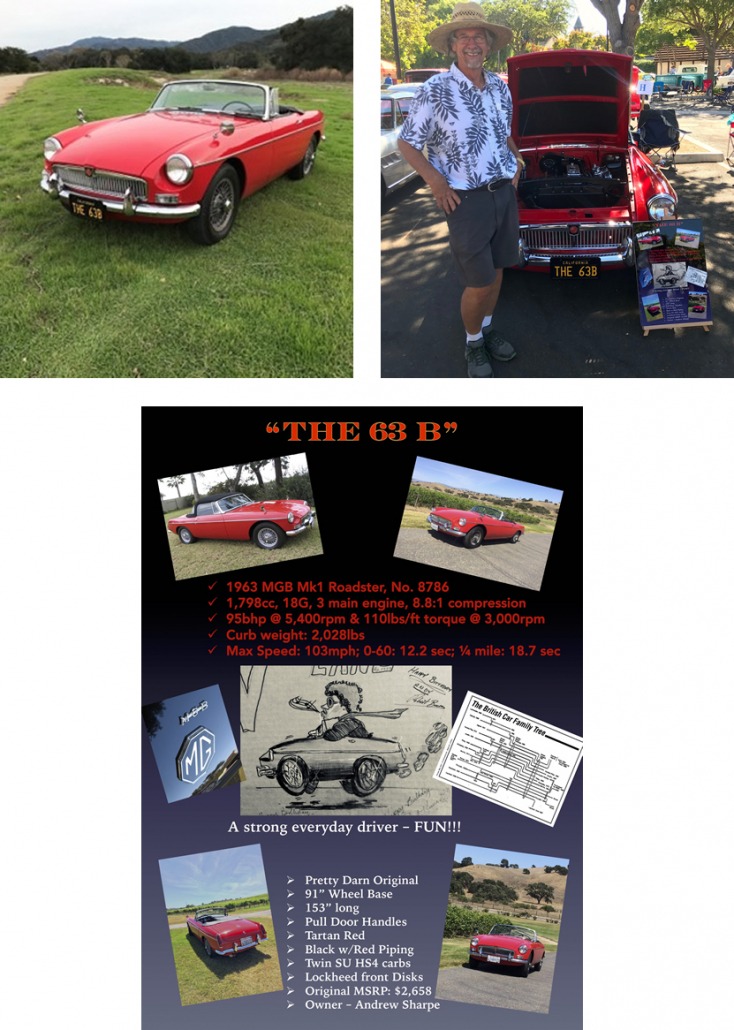

Now, after 44 years of getting a paycheck, retirement has bought me a 1963 MGB. A beauty it is.

I am happy to be continuing my visits to Moss Motors in Goleta, CA. We’re counting 51 years of buying parts from Moss Motors. Maybe not a record, but Moss has been there for me (and my brothers and sister) and has kept me on the road with many happy memories.

SafetyFast!

Andrew Sharpe

Member 124841